Cylindrical-conical fermentation tank CCT is stainless steel (AISI 304 – 1.4301) vessel mostly used for main fermentation of the beer or other beverages. This type of tank can be used also for maturation, lagering or as a serving tank – bright beer tank. With design of 3.0 Bar pressure man can call this tank also „universal tank“, tank for all beer production processes.

Product description:

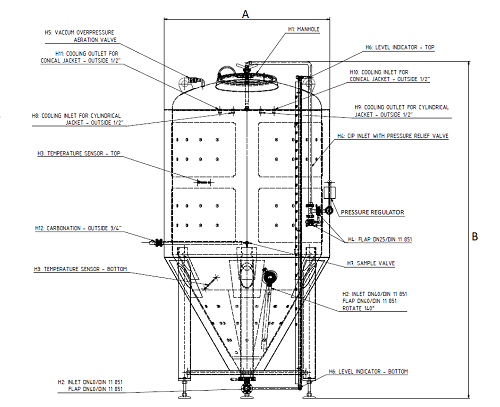

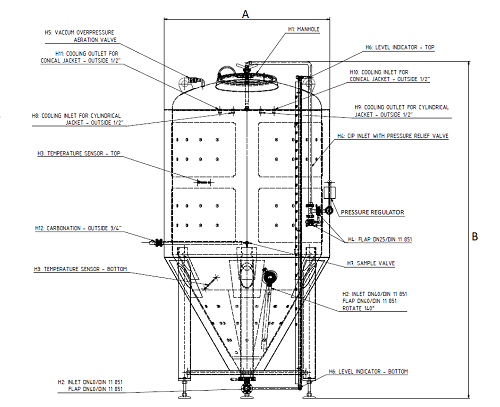

Tank is manufactured containing standardized dimensions and accessories, or according to individual customer requirements. Standardly it is equipped with two separate cooling zones – duplicators, outside jacket and PUR isolation. All stainless steel and pressure vessels from our production have PED certification and follow all EU standards. Range of our production is from 100 liters up to 20 000 liters vessels.

Technical specification:

|

Cylindrical-conical tank

|

Standard parameters

|

|

Net volume /HL/

|

|

|

Total volume /HL/

|

|

|

Total volume of glycol in duplicators /L/

|

|

|

External diameter /mm/

|

( B )

|

|

Internal diameter /mm/

|

|

|

Total height /mm/

|

( A )

|

|

Height of internal cylindrical part /mm/

|

|

|

Weight of empty vessel /kg/

|

|

|

Weight of loaded vessel /kg/

|

|

|

Material

|

Stainless steel AISI 304 / 1.4301

|

|

Isolation

|

PUR 70 mm

|

|

Angle of the conical part

|

60°

|

|

Max. working pressure in the tank

|

3,0 bar

|

|

Max. working pressure in duplicators

|

1,0 bar

|

|

Top

|

Domed

|

|

Bottom

|

Conical

|

|

Legs - adjustable

|

3 pcs

|

|

Glycol cooling zones

|

2 pc (1pc in Conical & 1pc in Cylindrical part)

|

|

Sanitation arm / shower

|

DN 32 DIN 11 851 / 1 pc

|

|

Inlet / Outlet for yeast

|

DN 32 DIN 11 851 / 1 pc

|

|

Inlet / Outlet for beer

|

DN 32 DIN 11 851 / 1 pc

|

|

Spray ball - removable

|

Rotation / 1 pc

|

|

Manhole

|

1 pc on the top

|

|

Over / Under pressure safety valve

|

1pc on the top, max. pressure 3,0 bar

|

|

Sample valve

|

1 pc

|

|

Temperature sensor

|

2 pc (1pc in Conical & 1pc in Cylindrical part)

|

|

Pressure regulator with manometer

|

1 pc

|

|

Surface inside the vessel

|

Ra ≤ 0,8

|

|

Certification

|

PED

|

Tank can be equipped with an extra accessory:

- level indicator with scale,

- manhole on the side / jacket,

- extra inlet DN 100/200 for dry hopping,

- carbonization candle,

- mirror polished surface inside the tank (Ra ≤ 0,4).

Our company supply stainless steel vessels to all Europe countries with maximal customer satisfaction and all necessary certification (CE / PED). Transport of the tanks is provided horizontally on a wooden pallet to avoid problems with large dimensions and safety during transport.

Price on request.

Contact form